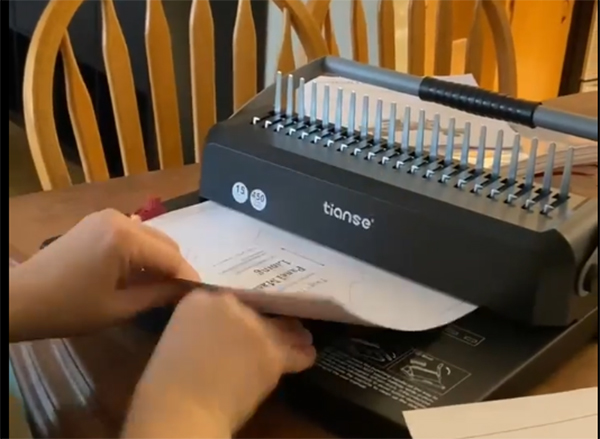

Regardless of whether you are using a comb binding machine or coil binding machine, you will sign that they are very simple to use, but you will also be at a loss for new machines or malfunctions in use. These malfunctions appear in all aspects. , Has a great impact on our work. Here, we will summarize the failures of the binding machine and provide some solutions.

1. The problem of paper jams during binding

This is a common problem when using binding machines. Some machines inevitably collide during transportation, causing internal parts to loosen, and the handle of the machine may get stuck in place during binding. The best way to deal with this problem is to insert the paper and continue punching, judging by the amount of paper and the position of the punched hole (please do not try to forcefully remove the paper. This will damage your equipment.) Then you can disassemble the corresponding machine and Reinstall the parts. If it is confirmed that the parts are damaged and cannot be repaired, please contact us for a replacement as soon as possible.

2. The holes are not aligned after punching (the holes are crooked)

The punching design of the binding machine is a labor-saving design. Its internal hole tooth arrangement is low on both sides and high in the middle. When punching, the hole is punched first in the middle, and then continues to both sides. When your document cannot be punched correctly, you may observe the arrangement of the holes and teeth inside to see if they are punched in this order. If the machine is jammed with paper scraps, you can remove them. Be sure to align the paper correctly next time.

3. One of the holes extends beyond the edge of the page.

Sometimes you may find an incomplete hole in one end (or both ends) of the document. The best way to prevent this is to use paper that fits the size of your device and makes sure to align the document correctly before lowering the punch handle. If your device has an edge adjustment guide, this may involve adjusting the edge adjustment guide.

4. It is difficult to turn the document pages after binding.

Finally, if you encounter this problem, it may be one of two things. First of all, you may have selected binding elements (combs, loops) that are too small. If this is the case, you can rebind your work with something bigger. Secondly, it may be a problem with the punching distance setting of your machine, which causes the binding of your work to be too close or too far from the edge of the page. Please refer to your user manual to determine the correct punch setting for the next use.

These are some of the most common problems people encounter when using comb or coil binding machines. Fortunately, these issues are easy to deal with, so you don’t have to spend a lot of time troubleshooting. You will be able to solve the problem and continue stapling. If you encounter a problem beyond the scope of this article, please check your user manual or contact our website to ensure safety. (Especially because trying to fix things yourself may inadvertently invalidate your equipment warranty.) Good luck with your project!

Post time: Nov-13-2021