Friends who have used the comb binding machine will definitely think that the most prone to failure of the binding machine pins of the binding. The pin is the core component of the comb binding machine and a good helper for book binding. So what should we do when the pins or dies failures occur in the binding machine we bought?

Next, we will disassemble each part for you to explain in detail. Help you troubleshoot and solve the problem.

If your Tianse comb binding machine is difficult to punch or unable to return to its original position after punching, perform as follows:

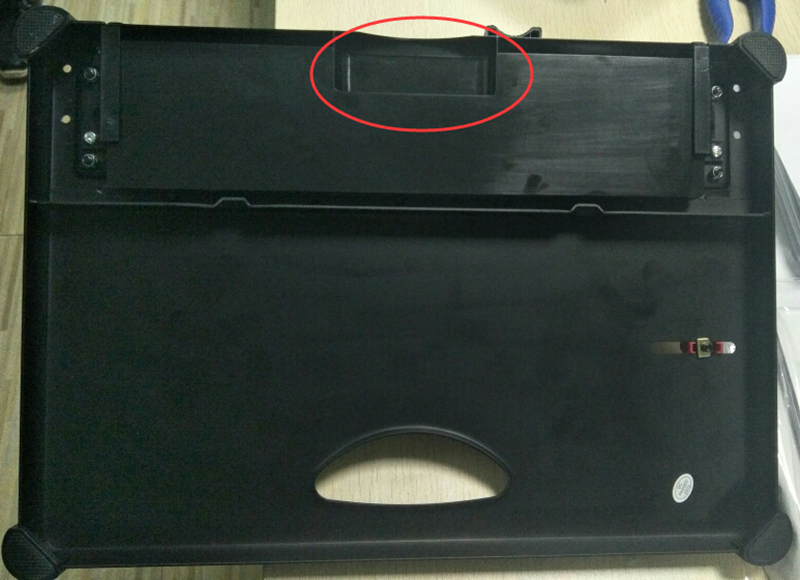

1. Turn the machine upside-down and take out the waste tray (as shown in Figure 1) at the base plate.

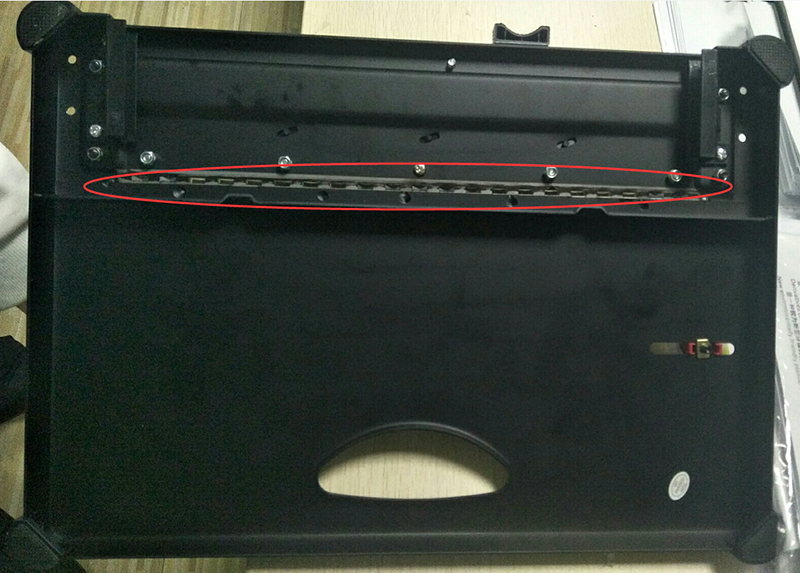

2. Gently press down the punching handle to the position as shown in Figure 2, and check if there are any paper scraps or other foreign matter.

a) If there are paper scraps or other foreign matter, then clean up the debris;

b) If there are no paper scraps or other foreign matter, then proceed to next step: remove the top cover to check the interior.

3. Unscrew the 4 fixing screws on the back plate, 2 screws on each end, as shown in Figure 3.

4. Place the machine to its upright position, remove the handle, and gently drag at the lower position beneath the round hole of the top cover (as shown in Figure 4) until its height exceeds the height of the handle’s fixed axis, then lift up to remove the top cover. As shown in Figure 5 after the top cover is removed.

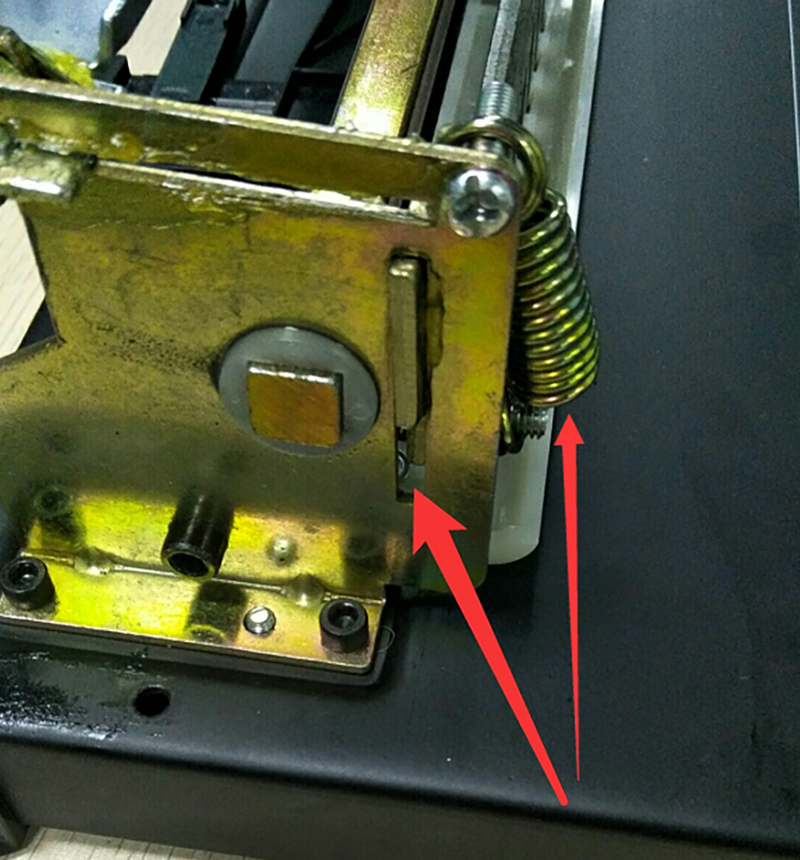

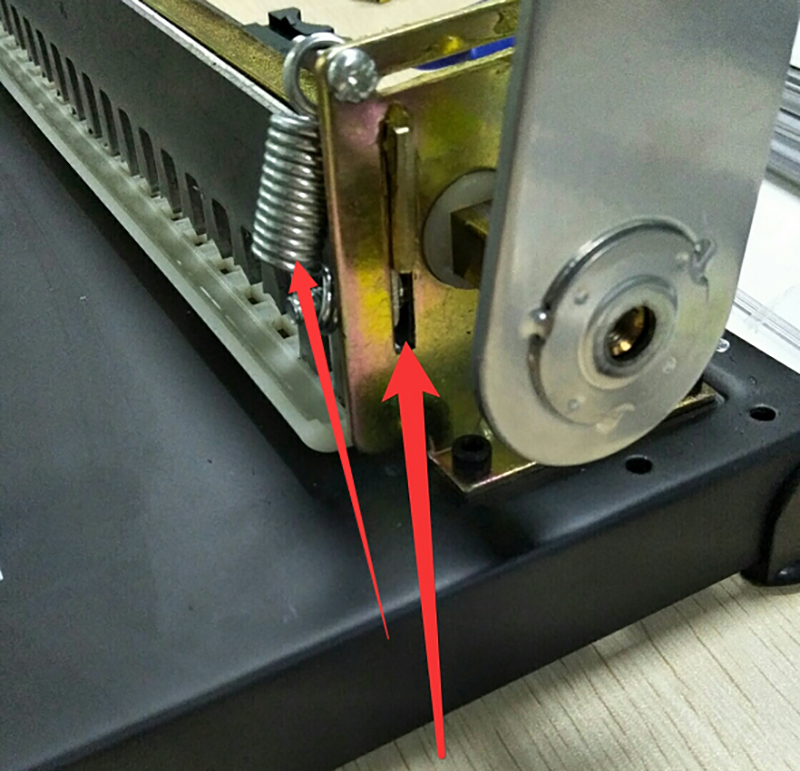

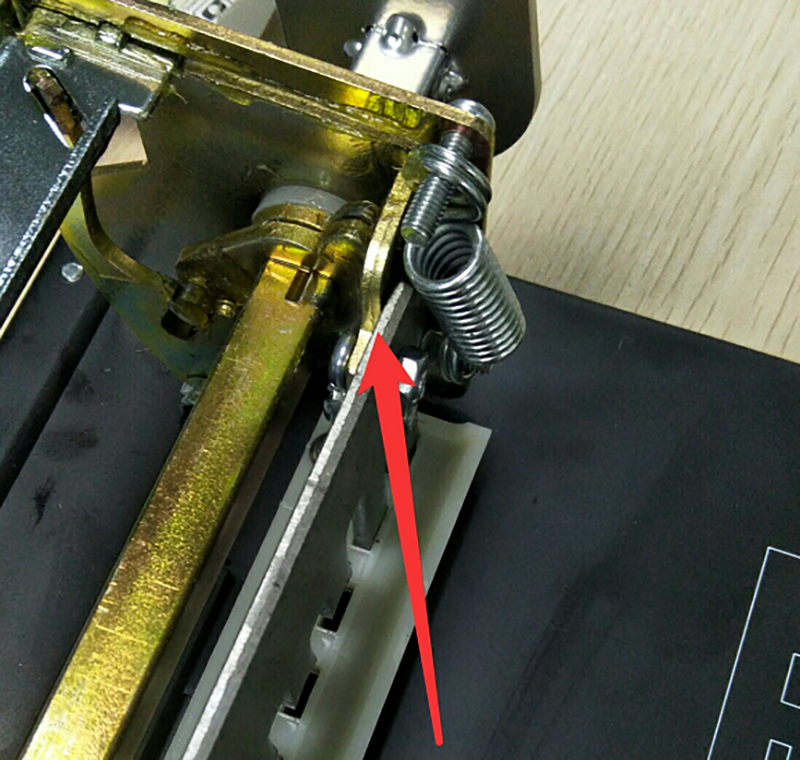

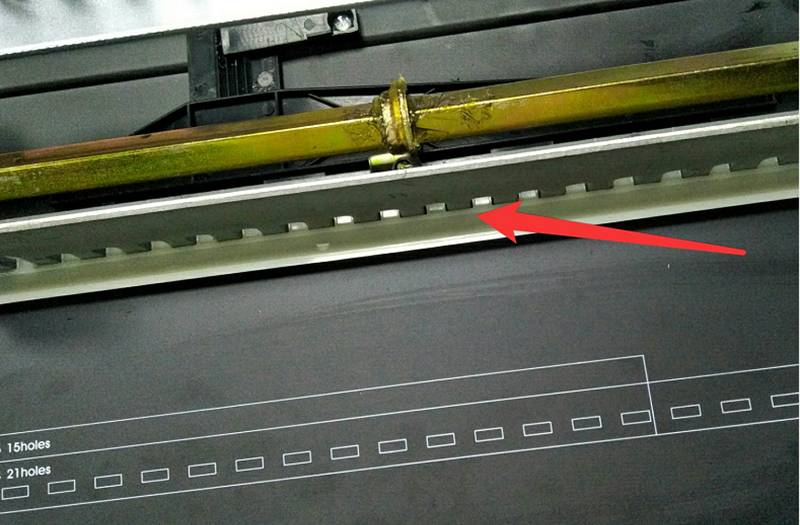

5. After the top cover is removed, check if the springs on both ends are loose and if the slots are clogged with debris (as indicated by red arrows in Figure 6 and Figure 7). If there is any debris, then remove the debris; if the springs are loose, mount the springs properly.

6. Check the upper right area as indicated by red arrow in Figure 8 to see if there is any foreign matter in the parts. Clean up the foreign matter if there is any.

7. Check as shown in Figure 9 to see if the guide pad blade is dislocated or if the cutting dies are deformed. Because the gap between the cutting dies and guide pad blade and holes on the base plate is quite small, you can use a wrench to press the cutting dies to determine whether the cutting dies are deformed or the guide pad blade is dislocated. If the guide pad blade is dislocated, then fix it with screws; if the cutting dies are deformed, then a repair is needed.

8. After completion of above steps, reverse Step 4 and Step 3 to install the machine back to its original status.

Post time: Aug-04-2021