Nowadays, 3D printers are faster, more flexible, and easier to use than ever before. Most of the desktop printers in use today are virtually of the FDM (Fused Deposition Modeling) type, which has gained increasing popularity because it’s affordable and easy-to-operate. However, even the best FDM 3D printers haven’t yet overcome one of their greatest limitations – prints coming out with visible layer lines. So in this article, we’ll introduce you 6 easy tips on how to smooth PLA prints since PLA filament is one of the two most commonly used materials in FDM 3D printing.

PLA (Polylactic Acid) 3D printer filament is the default recommended material for many desktop 3D printers. It is available in a full array of colors and can be used in a wide range of printing applications. PLA is well-known for its lower melting temperature and ease of use (no heated bed required), plus it’s low-warp, odorless and offers a glossy finish. What’s more, PLA filament is also one of the more environmental-friendly material available as it is made from renewable resources (corn-starch, sugar cane) and requires less energy to process compared to traditional petroleum-based materials. Though an unfinished PLA print is still perfectly functional, its surface finish and visual appear can be greatly improved even with the most basic smoothing techniques.

1. Sanding

As the most commonly used finishing technique for 3D-printed parts, sanding is an inexpensive, effective and proven method to achieve a smooth finish. Sanding gets rid of the outermost layer of PLA material, which greatly reduces the number of noticeable ridges on the surface of your 3D print. You’d better use multiple grits of sandpaper to achieve optimum results. Start with a coarse 200 grits sandpaper, then move up to 400, 600, 800, 1000, 1500, 2500 up to 3000.

Keep in mind to sand in a circular motion against the grain of the layer lines so that the finish doesn’t come out with a visible direction bias. Also remember not to sand too fast as the heat produced by friction would be enough to melt the PLA plastic. Pay due attention to small details in the 3D print, so your finish comes with consistent quality. The more time you spend sanding your PLA prints, the smoother finish you’ll get.

2. Polishing

When PLA smoothing with sandpaper, sanding alone will never completely remove layer lines. One method that works well is to apply polishing compounds to fill in any remaining layer lines. Polishing compounds are usually sold in bars, each with different grades, similar to sandpapers.

To apply the polishing compounds, simply apply a small amount on a soft cotton cloth and rub this onto the surface of your 3D print in small circular motions. What’s more, solid polishing compounds are also highly compatible with buffer wheels which can greatly accelerate the polishing process. Just the same with sanding, keep in mind that buffing generates friction and heat. Make sure that you’re moving at a low speed when PLA smoothing with a buffer wheel.

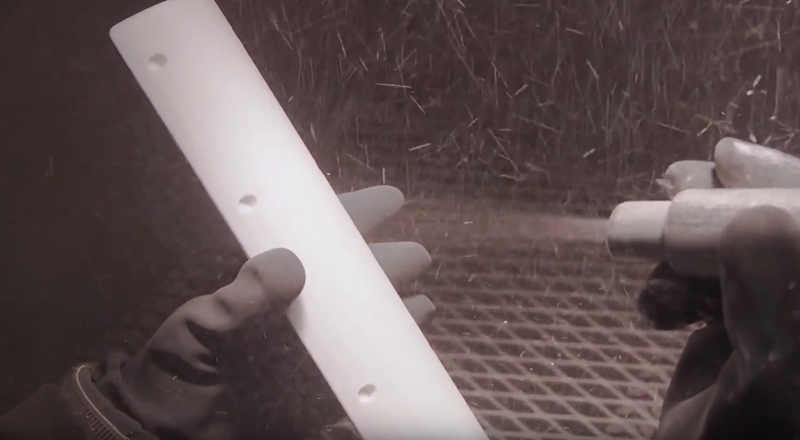

3. Bead Blasting

Bead blasting sprays tiny, plastic particles at a 3D-printed part inside an enclosed chamber to create smooth finish in approximately 5-10 minutes. As for this smoothing technique, an operator holds a nozzle that sprays small beads of media at a 3D-printed part to get rid of layer lines. Bead blasting is flexible, as it works with most FDM materials. This process leaves your PLA prints with a smooth finish which looks like a uniform matte finish.

One of the bead blasting limitations is the part size. Since the process takes place in a closed chamber, the maximum part size is 24×32×32 inches. Moreover, given that 3D-printed parts are bead-blasted manually, they are finished one at a time and, therefore, cannot be mass finished.

4. Priming

A fourth method for smoothing your PLA prints is to use a high-fill primer spray paint in combination with the sanding technique. For example, you can use a cheap can of Rust-Oleum to get the best finish. After you’ve sanded your PLA print with the highest grit sandpaper, simply spray an even and thin coat of Rust-Oleum onto your print.

The strength of using Rust-Oleum is that it can be sanded to achieve a smooth finish. You can sand the primer again to the plastic so that it will only remain in the depressions of the layer lines. You may repeat this process until all your PLA print’s imperfections have been fixed.

5. Heating

A less popular method for PLA smoothing is to use a heat gun along the surface of the print. As this technique uses a considerable amount of heat and requires a certain amount of skill & practice, doing it improperly may easily result in ruining your PLA print altogether.

To smooth your 3D print, simply point your heat gun at the PLA print and maintain slow and constant motion. Do not let the heat gun linger on any single area as this can easily melt the PLA plastic. Moreover, since any heat treatment will unavoidably generate fumes despite the fact that PLA is well-known for being odorless when heated, you need to make sure that you’re heat finishing your PLA print in an open or well-ventilated area.

6. Painting

The last option for PLA smoothing and finishing is to use painting technique. Again after your PLA print is smoothed with coarse sandpaper, you can use different types of paint to get smooth finish and enhance aesthetic appeal. For complicated organic colors, you can use acrylic paints and mix them while you’re painting to achieve the desired effect. Another alternative is to use spray paint. However, after your paint job, it is best to seal your PLA prints with either a mat or glossy clear coat to safeguard your colors.

To truly bring your 3D printing craft to a new level, you’ll have to learn and master a few smoothing and finishing techniques. As you gradually refine your skills, you’ll be able to create quality PLA prints with smooth finish and aesthetic attraction. Feel free to use TIANSE PLA 3D printer filament and try above 6 easy tips on how to smooth PLA prints to get quality 3D-printed PLA models with smooth finish and aesthetic appeal. Happy 3D printing!

Post time: May-24-2019