One of the most essential parts of a 3D printer is the extruder which pushes filament to the hot end to be melted and extruded. All extruders share three key components: s stepper motor, a drive gear, and an idler. Though the parts of extruders are virtually all alike, there are two different types of extruders – Direct extruder and Bowden extruder. So, what’s the difference between direct extruder and Bowden extruder? Which one is better? In this article, we’ll explore the advantages and disadvantages of Direct and Bowden extruders respectively.

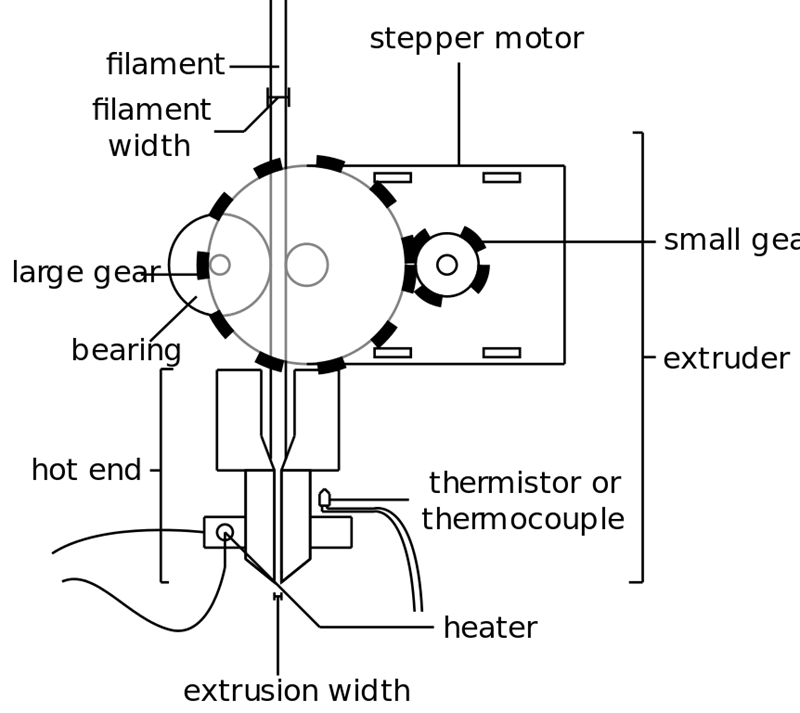

Direct Extrusion

The difference between Direct Drive and Bowden Drive extruders is the location of the extruder in relation to the hot end. Direct Drive extruders, as the name suggests, are attached to the hot end directly and are a part of the hot end.

(Direct Extrusion Diagram, Source: Wikipedia)

Since Direct Drive extruders are mounted above the hot end with little space between them, a Direct Drive extruder keeps the distance that 3D printer filament travels from the extruder to the hot end to a minimum. This leads to the major advantages of Direct-style extrusion.

Pros:

- Better Extrusion and Retraction: Since there is less distance for the filament to travel from the extruder to the hot end, the motor can easily push the filament through the nozzle, allowing for easier extruding and retracting. The filament is more responsive to the extruder, which means that there is less string and oozing that occurs due to poor retraction and leads to higher quality prints.

- Less Powerful Motors: The minimum distance between the extruder and the hot end means less force is required from the stepper motor than in a Bowden extruder, meaning two things: 1) There will be less probability of slipping filament via the hobbed bolt as the extruder will be more gentle on the filament; 2) A smaller stepper motor may be utilized to drive the extruder, thus producing a lower energy draw and less mass for the gantry.

- Wider Range of Filaments: Direct Drive extruders are capable to print a wider range of 3D printer filaments, particularly flexible and abrasive filaments as well as other exotic materials. Though flexible materials can work with Bowden Drive extruders, better print results can be yielded with Direct-style extrusion.

Cons:

However, the location of the Direct Drive extruder also results in its main disadvantages. With the extruder mounted to the print head, weight is obviously added. This extra mass to the gantry can cause more backlash, overshoot or frame wobble when printing at faster speeds than equivalent Bowden extrusion systems.

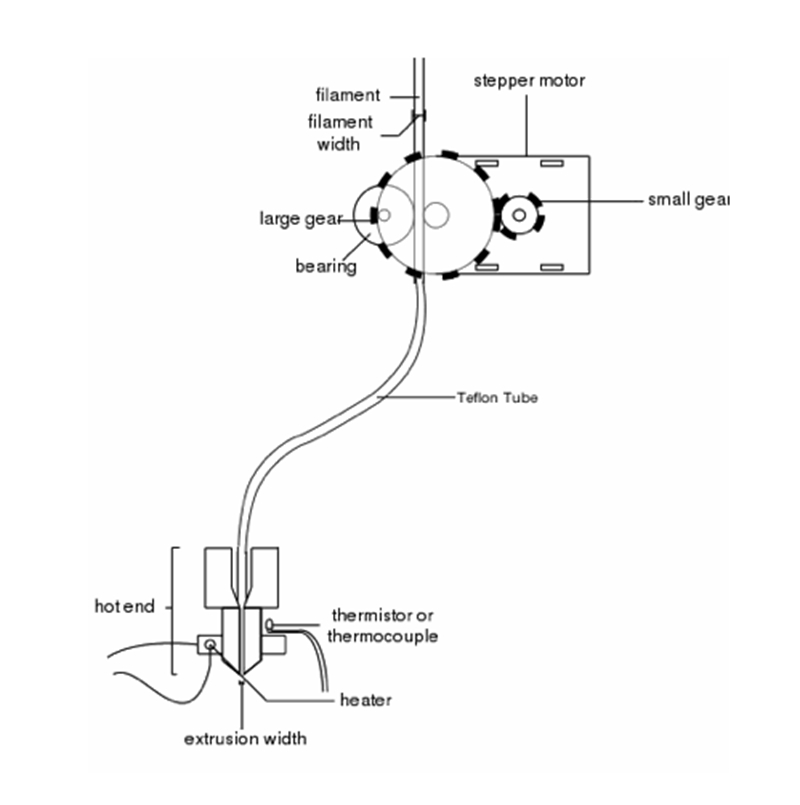

Bowden Extrusion

Unlike Direct Drive extruders, Bowden Drive extruders are not directly attached to the hot end or print head. A Bowden Drive extruder is most often attached to the printer’s frame. The filament is then fed to the hot end using a Bowden tube (also referred to as Teflon tube or PTFE tube).

(Bowden Extrusion Diagram, Source: 3dprint.com)

Pros:

- Reduced Weight of Print Head: The greatest advantage is the reduced weight of the print head. As the extruder is removed from the print head, there is less weight on the print carriage.

- Faster, More Accurate and Higher Quality Prints: With lighter print head, a 3D printer using a Bowden Drive extruder can print faster, more accurately and more precisely. This can lead to either higher quality prints or quicker prints, because the print head is moving at higher speeds.

- Compact Size, Occupy Less Space: Bowden Drive extruders are typically more compact, thus taking up less space than Direct Drive extruders.

Cons:

- Greater Retraction Distance and More Powerful Motor: Bowden Drive extruders need a greater retraction distance and a more powerful motor than Direct Drive extruders, which is resulted from the increased friction on the filament in the Teflon tube.

- Slower Response Time and Less Responsive System: More friction in the Teflon tube also leads to slower response time and less responsive extrusion system, thus more stringing and oozing on the print as well as more resistance and drag with the filament.

- Smaller Range of Filaments: Bowden Drive extruders cannot use as many filaments as effectively as Direct Drive Extruders. Although they can still print flexible filaments like TPU or TPE, these filaments tend to bind in the PTFE tubing. Moreover, Bowden Drive extruders cannot use abrasive filaments as these filaments will wear away the inside of the PTFE tubing.

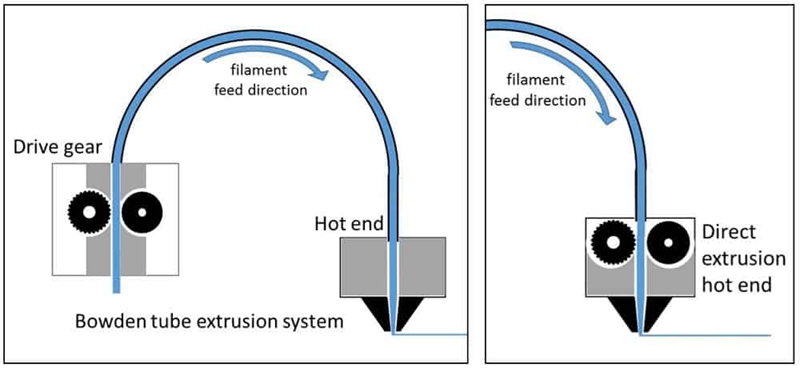

Direct or Bowden? Which One Should I Choose?

So which extrusion system is better? It depends. There are several factors to consider before deciding on a Direct Drive or Bowden Drive extruder.

Diagram of Bowden (left) and Direct (right) Extruders,

(Source: 3dprinterpower.com)

For a Direct Drive extruder, it is important to make sure the printer has as stable a frame as possible to handle the added weight, while for a Bowden Drive extruder, a completely constrained extrusion system is vital to ensure that the filament moves where it should without binding. If you want to use flexible filaments like TPE/TPU, abrasive filaments or other exotic filament materials, a Direct Drive extruder would suit you best; if you want faster speed and are using a more standard filament, a Bowden Drive extruder would work just as well.

After reading this article, we hope you have a better understanding of the two different types of extruders: Direct Drive extruder and Bowden Drive extruder, the differences between them, and the pros and cons of Direct and Bowden extrusion systems. If you ask our opinion on choosing between a Direct Drive and a Bowden Drive extruder, we’d recommend a Direct Drive extruder for the majority of people, while a Bowden-style extrusion might be more useful to those with experience and time to tune their machine.

Post time: Aug-26-2019