Printable foods, printable stem cells, printable artificial limbs, printable shoes — almost everything are 3D printable as long as you have the 3D printer, the software, and the material. Truly, the applications of this earth-shaking technology are endless. However, most users are not aware of the health risks that are involved when a 3D printer is installed in a non-industrial environment with poor ventilation. Today, let’s take a cold, hard look at an important question that most people are concerned about: Is 3D Printer Filament Toxic?

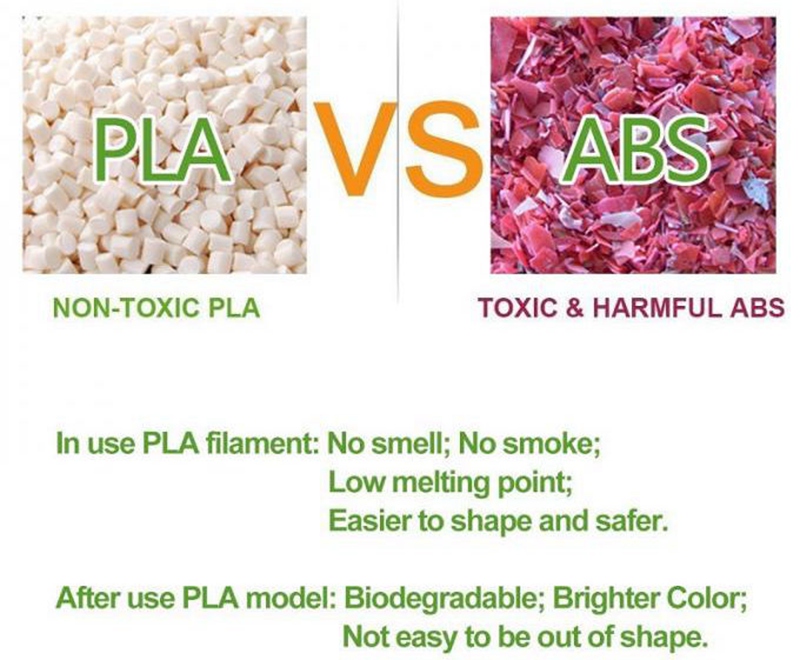

It is easy to understand that melting a thermoplastic material comes with pollution. Normally, thermal decomposition of ABS is known to have toxic effects. It is also known that PLA is much safer than ABS. But why is the case? What exactly are the potential health risks involved for each material? Let’s first look into two terminologies used in industry: Ultra Fine Particles (UFPs) and Volatile Organic Compounds (VOCs).

UFPs

All FDM 3D printers are emitting UFPs. These ultra fine particles are defined as particles with a diameter less than 0.1µm. They can easily invade the human body and directly impact the lungs. There are massive cardiovascular health risks associated with inhalation of UFPs. Not only can these particles increase risks of asthma, but they can also become carriers of toxins inside the bloodstream.

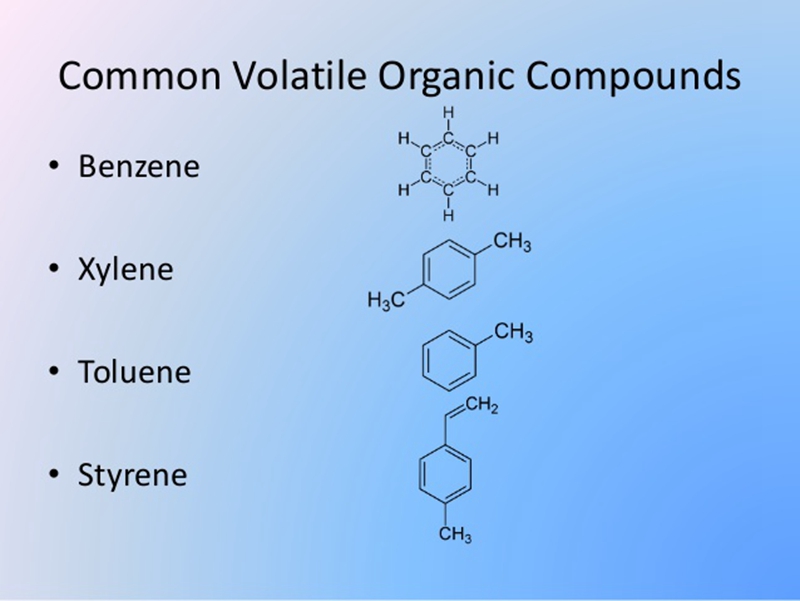

VOCs

VOCs also pose health problems. They are airborne chemicals with a high vapor pressure at room temperature, which makes them easy to evaporate in the air. Inhalation of VOCs like benzene and methylene chloride has been linked to cancer. The Environmental Protection Administration (EPA) classifies VOCs as toxic pollutants.

Let’s have a quick look at the two most common 3D printer filaments used in FDM 3D printing: ABS and PLA.

ABS is short for Acrylonitrile Butadiene Styrene. Styrene is one of those hazardous volatile compounds – it’s toxic and maybe cancer-causing. Fortunately, PLA (Polylactic Acid) breaks into lactic acid – the same chemical that makes you sore after exhaustion – so there’s no health threat there.

How To Improve 3D Printing Safety

1. Increase Awareness of The Risks

One solution is to increase the users’ awareness of the potential risks of toxic emissions from 3D filaments. Consumers like students, children, and employees usually are not aware of the health risks associated with 3D printers and filaments. Inform them about the potential risks and minimize the time that they are working in the direct environment of the 3D printer.

2. Proper Airflow & Underpressure

The safest and most viable option for using an FDM 3D printer is to direct the particles away from the users by harnessing the airflow and underpressure. You can improve your 3D printing safety by creating underpressure around your 3D printer, which will fume out of your working environment. Particularly, if you’re printing with ABS, do use a filtration system of some kind.

3. Use Ways to Minimize Exposure

You can also use the following ways to minimize exposure:

a) Using the lower end of the recommended print temperature of the material used.

b) Use PLA filament since it has lower UFP emissions. For example, made from authentic and non-toxic materials, TIANSE PLA 3D printer filaments are odorless, all natural biodegradable and eco-friendly with good quality and high performance.

In a nutshell, the development of 3D printing is going fast, however, the development of 3D printing safety is lagging. Instead of worrying about the question “Is 3D printer filament toxic?”, the best way to ensure 3D printing technology evolves in a way that we can maximize its benefits and limit any risks involved is to tackle the potential health risks of 3D printing materials early.

Post time: Apr-10-2019