To make our customers have a wonderful and successful experience of TIANSE 3D printer filament during 3D printing, we have gathered the most common print quality problems encountered and frequently asked by our customers. We specially made this 3D printing column featuring different articles, in the hope to provide useful recommendations or solutions for our customers and help them better resolve the relevant print quality issues.

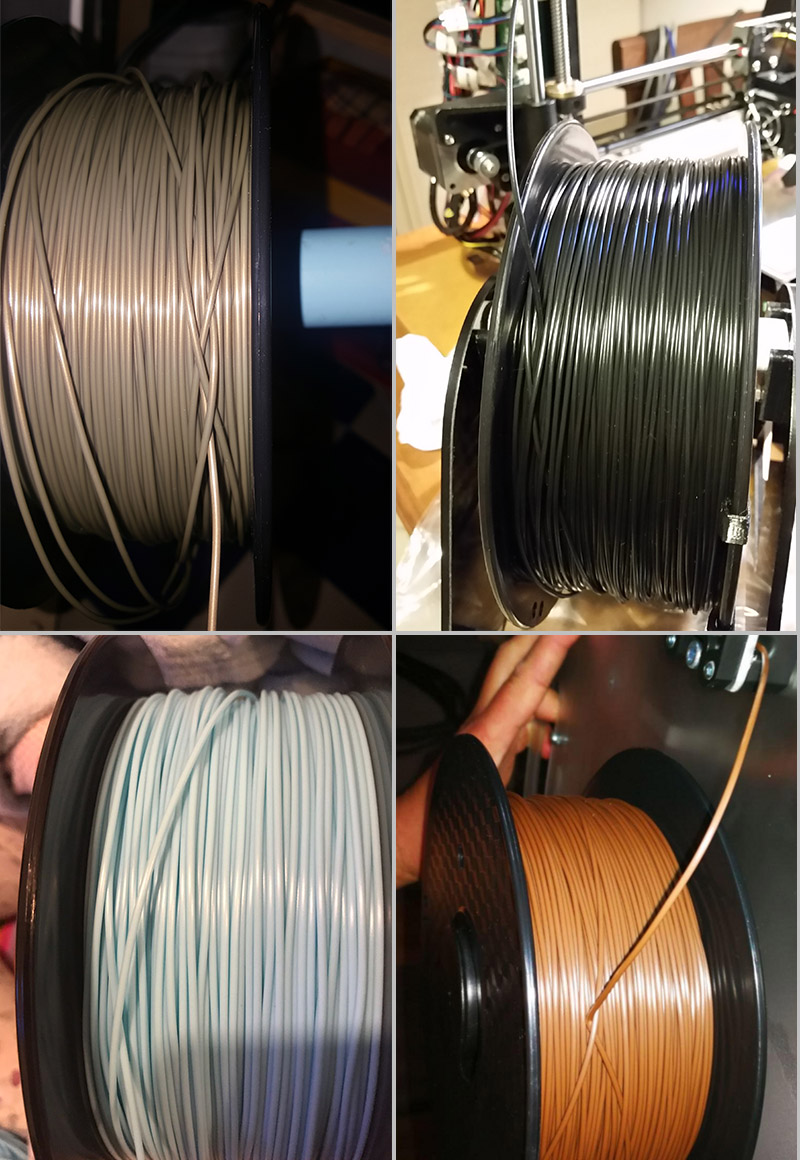

Today, let’s explore several reasons leading to filament tangling issues and focus on how to cope with 3D printer filament tangles.

1. Improper Handling of Filament End

If you take out the unused filament without proper handling of the filament end, it will cause tangling problem during the next-time use. Therefore, you’re suggested to properly arrange the end of the filament.

2. Nozzle Too Far Away

Tangling problem may arise if the distance between the consumables and the nozzle is too far away. When connecting the filament to use during printing, if greater pull force is applied in order to release more filament, it will cause the spool to automatically rotate several turns, thus causing tangling issue.

You need to ensure that the spool is capable to spin freely and that the plastic is easily being unwound from the spool. If the filament gets tangled or the spool has too much resistance to rotate freely, it will affect how evenly the filament is extruded through the nozzle.

How To Prevent This From Happening Again?

One cardinal rule I suggest any person new to 3D printing to follow: never let go of the end of your filament unless it is in the extruder and tensioned down or in a spool hole and tight enough not to unspool. You should always maintain control of the end of the filament to prevent this from happening.

In our next article, we’ll discuss how to deal with the issue of “Print Not Sticking To The Bed”.

Happy 3D printing!

Post time: Nov-15-2018