As a beginner 3D printing hobbyist, when we waited expectantly for the arrival of the first 3D printer we purchased, we always considered how much 3D print filament I need to prepare for printing? Maybe some printer vendors will give away a small roll of filament along with the printer, but this is only enough for us to carry out preliminary printing and debugging, which is not enough for my 3D printing needs!

How many filaments do we need to use for 3D printing? Generally speaking, I need at least two 1KG 3D filaments, and the other filament is used as a spare (you don’t want to worry about the disconnection after printing for a few hours for the printer). If it is a 5kg filament, it can be used by us. For a long time.

No matter what kind of filament is used, when using a 3D printer for the first time, we have to debug the printer, and a lot of filaments will be consumed when calibrating and benchmarking the printed parameters. Once the debugging is completed and the 3D model is officially printed, the filament loss will not be so great, of course, the loss of various failed items must be counted.

How to Measure your Filament?

(Source: Tianse / Black PLA)

Before that, you need to understand some basic knowledge about filament measurement.

Generally, the weight of the 3D printer filament sold on the market is 1KG spools. In addition, there are many products weighing 5KG and 10KG. In general, it will cost less to buy a heavier 3D filaments.

The length of 1KG 3D filament is about 330M (1,099 feet), 5KG can be understood as 330M*5, and the length is five times that of 1kg filament. Most of the products are 1.75mm wide.

There are different densities for different materials, varying spool weights, and different filament weights. Sometimes, the roll will have its spool weight written on it. When its not written on the side, the easiest option is to google the spool weight from the manufacturer. Often times you’ll find a chart someone made showing all the spool weights for various brands.

Once you have the spool weight, weigh your used filament roll on a scale to see how much it weighs (in grams). Once you have that number, you are ready for the simple formula:

Weighed Roll – Spool Weight = Remaining Filament Weight

Using this formula, you can look in your slicer and see if you have enough left on the roll.

How Long Does a 1KG Roll of Filament Last?

1KG is the most commonly used weight in the filaments market. Today we use 1KG of 3D filaments to illustrate. How long can a roll of 1KG filament last? Obviously, the length of time that everyone uses the filament varies, depending on the printer model used and the size of the object printed. The average 3D printer user has their 1KG spool of filament for just over a month before it needs replacing.

How long a roll of filament is actually used depends on how often you print and what you print. Print large-capacity items and you can use them in a few days. Some infrequently used or small-volume items may not be used up in a month. If we need to measure, we can download a slicer like cura to help us test, use it on the model to be printed, and they will tell you how many filaments are used.

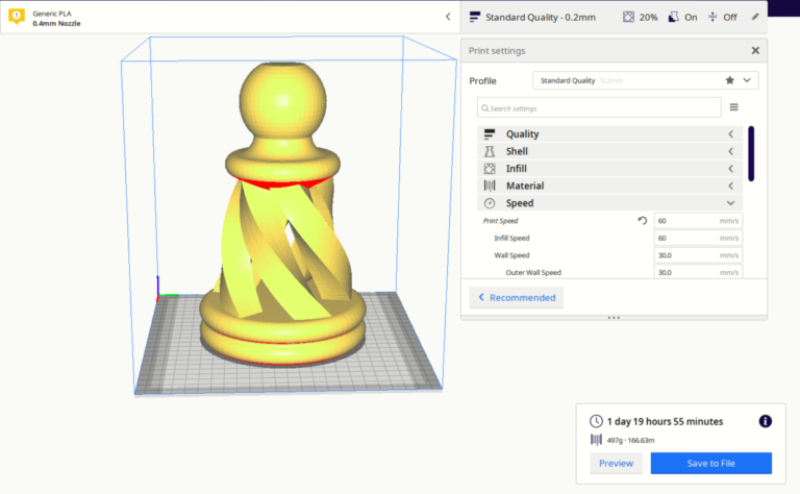

If you have a relatively large model to print, you can set your parameters and the model to be printed on the cura software, and they’ll tell you how much filament is used.

For example, in the following model, cura calculates that the weight of the 3D filaments to be printed is 497g, which can continue printing for about 45 hours. We can also adjust the length of printing and the weight of the required filaments by setting the size of the nozzle. The larger the nozzle sets, the shorter the printing time and the more filaments required for printing. No matter what, you can set the nozzle flow rate according to your wishes and the items printed.

(Source: 3dprinterly /Michael Dwamena)

In addition, larger-volume printers are also prone to consumption of filaments, and they leave more space for printing large projects.

How Do I Make My 3D Printer Filament Last Longer?

To extend the service life of the filament, the most important thing is to reduce the usage of the filament and reduce the unnecessary loss of materials. Next we will explain several aspects. Over time, these practices will save you a lot of money and give you more funds to support your 3D printing road.

control size

This is the most obvious way to extend the life of 3D printer filaments. If the item is not a functional printing accessory or the object does not need a large size, consider reducing it by 25%-50%. Even if it is only reduced by 5-10%, it may have a significant impact on the number of filaments and printing time. But this does not affect your print quality.

You might think that this has disadvantages, such as making weaker parts, but if you use the right method, you can actually reinforce the part and save filament and printing time.

High utilization Infill setting

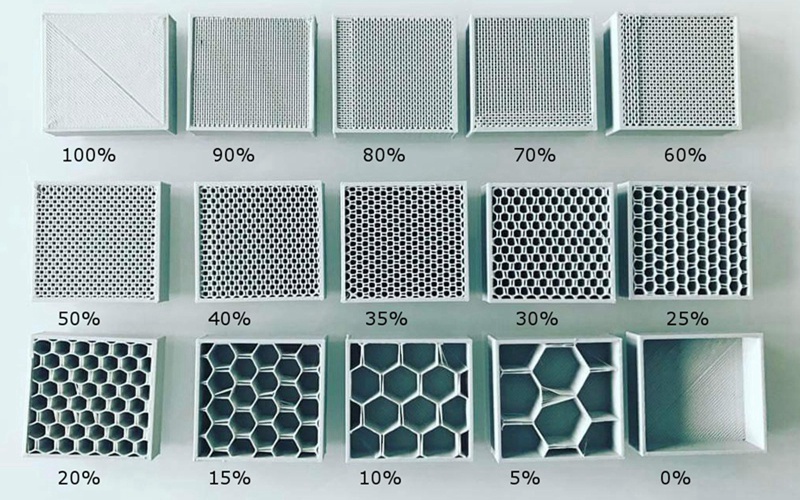

Infill is an element that gives weight and internal structure to the printed item. Although it is possible to print things without infilling (such as our common vase), there are more items that need to be infilled.

When using infilling, the infill rate can be appropriately reduced. Most slicers have a default infill of 20%, but many times you will be satisfied with items printed with 10-15% percent infill rate or even 0%. Filling with more material does not mean greater strength. When you reach a very high fill setting, the effect of the printed project may start to backfire.

If we don’t set such a high filling rate, how should we decorate and infill these hollows? I recommend using infilled patterns for decoration. Hexagonal and cubic patterns are usually the best choice for this, which not only saves materials, but also saves more printing time.

Find ways to reduce support materials

Most 3D printing will rely on support materials, and we can orient the model to use as little support as possible. Sometimes this involves digitally cutting the model into small pieces before printing.

You can use the 3D printing slicer APP to effectively reduce the support material. Different slicers have different support structures, which means different numbers of filaments. You must use a different slicer to see the slicer you like.

Reduce unnecessary rafts

A raft is a thick layer under your part that adheres extremely well to the bed. Using one of these will drastically improve your print’s chance of succeeding, but at the cost of a little extra filament.

Usually, in many cases, the use of rafts can be reduced or eliminated, and this needs to be carefully weighed by you. Once it can be omitted, it will bring higher benefits to your 3D printing business.

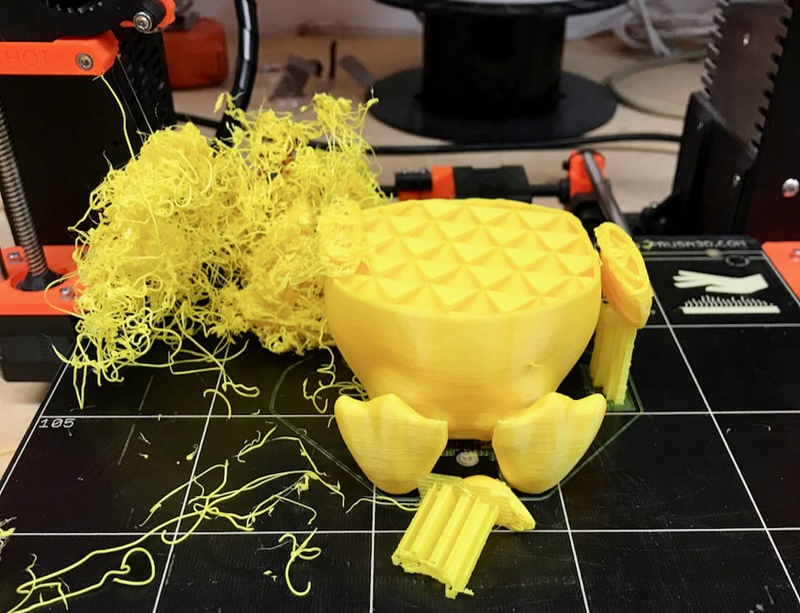

Reduce failed printing

Whether you are a novice or a veteran, there will always be many failures in the 3D printing process. Once the printing fails, we will ruthlessly discard the item in the trash. This is also one of the most wasteful places for 3D printer filaments. Regarding how to avoid printing failures and repair failed item, you can reduce the loss of printing and the consumption of printing consumables through the steps we have mentioned before.

3D printing is a fulfilling thing. We always look forward to printing various exquisite models to achieve happy printing. But 3D printing is also a job that requires continuous investment of time and energy. In addition to the accumulation of accumulated experience that allows us to be more proficient in reducing printing loss, effectively extending the life of the filament will help us to stably output excellent works.

Post time: Feb-07-2021