It is of great importance that the first layer of your print is strongly bonded to the build platform of the printer so that the remainder of your print can be securely built on this foundation. If the first layer fails to stick to the build platform, it will cause problems later on.

There are many different methods to deal with the first layer adhesion problems, we therefore investigate several typical causes below and put forward 5 easy ways to deal with print not sticking to the bed accordingly.

Cause 1: Build Platform Not Level

If you have difficulty in getting your first layer to stick to the build platform, the very first thing you should do is to check that your printer’s bed is flat and level. If the bed is not flat and level, one side of your bed may be too close to the nozzle, while the other side is too far away. Make sure your printer’s bed is flat and level cause a perfect first layer needs a flat and level bed.

Cause 2: Nozzle Too Far Away from the Bed

After your bed has been leveled properly, you still need to ensure that the nozzle is starting at the correct height relative to the build platform. Your aim is to locate the extruder the perfect distance away from the build plate: neither too far nor too close. To achieve good adhesion to the build plate, you want your filament to be adhesive against the build plate. You can adjust the 4 screws at the corners of the hot bed, turn anticlockwise the screws and the hot bed will move up. Turn a little at a time to reduce the distance until there is appropriate room for filament extrusion. Keep in mind to only make small adjustments to this setting.

Cause 3: First Layer Printing Too Fast

When you extrude the first layer of plastic, you want the plastic to be properly stick to the surface of the build platform prior to starting the next layer. If the first layer is printed too fast, the plastic may not have sufficient time to bond to the build platform. It is thus very helpful to print the first layer at a slower speed so that the plastic has enough time to stick to the bed.

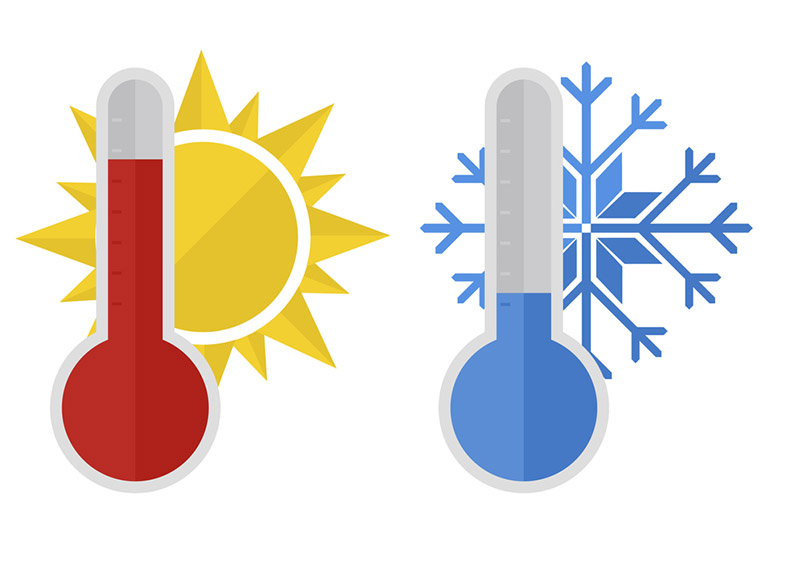

Cause 4: Temperature or Cooling Settings

Plastic tends to shrink when its temperature is down. To print high-temperature materials like ABS, 3D printer contains a heated bed to help cope with these issues. If the bed it heated to keep a temperature of 70-100℃ for the whole print, it will keep the first layer warm so that it does not shrink. Generally speaking, PLA tends to adhere well to a bed that is heated to 40-60℃, while ABS normally works better if the bed is heated to 70-100℃. For TIANSE PLA filament, what’s worth mentioning is that we suggest your bed to be heated to 50℃ in winter.

Note: Our TIANSE PLA is modified and is not “pure” PLA. Though pure PLA has good viscosity, it is brittle and it is quite difficult during support removing. We specially modified our PLA to enhance its toughness and reduce its viscosity, in the hope to find a perfect balance between printing and support removing.

Cause 5: Tapes, Glues and Materials

Different plastics tend to adhere better to different materials. If you are planning to print onto these surfaces directly, it is always advisable to make sure that your build platform is free of grease, dust or oils before printing. Using some water or isopropyl rubbing alcohol to clean your printer’s bed can make a big difference.

There are several kinds of tapes that stick well to common 3D printing materials. For instance, PLA tends to stick well to blue painter’s tape while ABS tends to stick better to Kapton tape. You can use temporary glue or spray on the surface of the build platforms. If everything else has failed, glue sticks, hair sprays, and other sticky substances may be helpful as well. Feel free to experiment to check what works best for you!

In this article, we have explored several typical causes for the issue of print not sticking to the bed and have come up with some useful recommendations accordingly. We hope all these information will be helpful when you’re using TIANSE 3D printer filament for your creative 3D printing projects!

Happy 3D printing!

Post time: Nov-23-2018